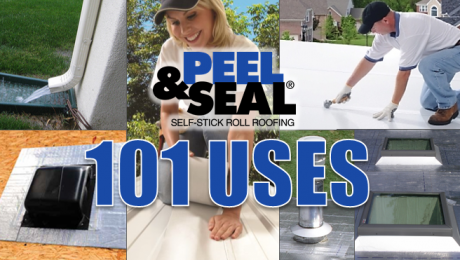

Peel & Seal® is so versatile, it can be used to waterproof almost anything and we have a list to prove it. Over the years, we've heard from customers around the globe telling us how they've used Peel & Seal in ways we never dreamed of. Just for fun, we thought we'd publish the uses we have received.

Learn the things you should avoid when using SBS-Modified construction materials on the job site. Save yourself a lot of heartache and mess by following these simple rules of using SBS self-adhering membranes.

Learn how the devastation of El Nino in California led to the development of FutureFlash, a mechanically-attached waterproofing membrane used extensively on the West Coast. An interesting read for sure.

Waterproofing parapet walls can be a tricky proposition - learn some of the basic concepts for a successful waterproofed installation.

Ultra HT Wind & Water Seal can be used in vertical applications behind metal panel sidewall systems or metal-capped parapet walls where high heat is generated. Learn more about this specialized application.

Installing a self-adhering roofing underlayment takes some know-how and MFM offers these valuable tips for a proper installation.

Roofing codes are changing and one of those changes has been the requirement to seal the seams of the roof deck panels. Whether it is code or not, you’ll want to learn more about how to properly install MFM Roof Deck Tape for maximum waterproofing protection on your next project.

Waterproofing along the roof edge is a critical area that is prone to wind-driven rain getting under the shingles, which leads to wood rot. ShingleStarter was developed to protect this area with a unique approach to seal out this area to the elements.

MFM is proud to introduce DeckWrap™ PowerBond™ - a new, highly aggressive waterproofing membrane to protect decks and posts from premature rot and degradation.

Learn how the MFM PowerBond™ Adhesive System can help you install products in colder temperatures, while still realizing savings over comparable butly-based adhesive products. Same performance characteristics at a much lower price point to save material costs on your project.

FutureFlash® is a specially designed waterproofing membrane for use with stucco buildings. It is a patented product which as of today, has yet to experience a failure on the jobsite. Read more about this very unique product...

A growing trend is turning previously unusable outdoor living space into an oasis complete with tile, torches and plenty of smiles. You may also be contemplating installing tile or stone in place of or over traditional concrete. Many of these projects include upgrading an exterior balcony, patio or flat roof spaces above a garage or sunroom.

Building Codes are a part of every construction project. They affect the builder, distributor, manufacturer and building owner in one way or another. Until recently,specific codes had not been established for the group of building products commonly know as "window flashing tapes."

When it comes to installing metal roofing systems, contractors need to be aware of the high heat generated under these systems for total roof protection. Unless the underlayment installed is rated for high temperature applications, you could run into troubles down the road.

When the temperature drops and you have windows to flash, MFM provides two excellent products designed for these cold weather applications. WindowWrap PowerBond and WindowWrap Flex PowerBond are specifically designed to flash windows and doors in temperatures as low as 25°F (-4°C).

MFM Building Products produces a number of self-adhering, or self-stick, underlayments that typically have a minimum installation temperature. In general, MFM recommends installing its roofing underlayments in fair weather at temperatures at 50°F (10°C).